Mercedes-Benz launches Tomorrow XX, an initiative dedicated to sustainability

Tomorrow XX: Mercedes-Benz Unveils Ambitious Project for Almost 100% Sustainable Mobility

Sustainability has ceased to be a mere marketing concept and has become a cornerstone of the global strategy of automakers. Every volume manufacturer has developed major projects aimed at reducing the carbon footprint of vehicles throughout their life cycle.

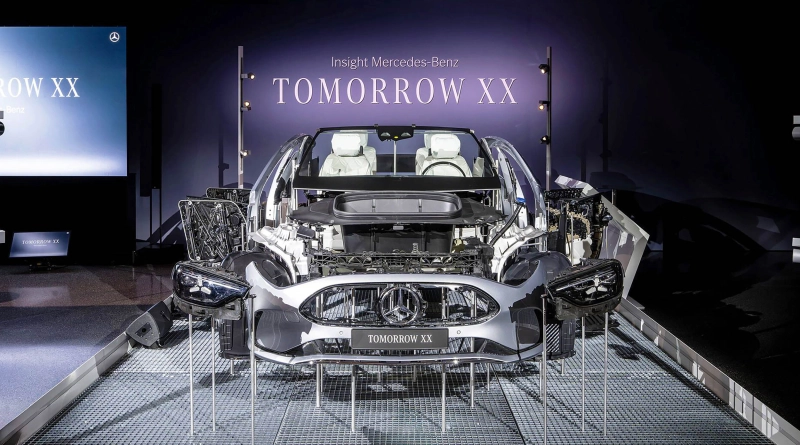

In this landscape, Mercedes-Benz, a pioneer of luxury and innovation, has just unveiled its revolutionary initiative: Tomorrow XX. This project is not just a promise, but a concrete roadmap to produce more environmentally friendly cars, based on an increased proportion of ecological and recycled materials.

From Concept to Series Production: EQXX and AMG GT XX Principles

The Tomorrow XX program adopts and expands the highly efficient and sustainable construction principles developed for the brand's visionary concepts: the Mercedes-Benz Vision EQXX (famous for its record-breaking efficiency) and the AMG GT XX.

The main objectives are clear:

- Massive reduction of carbon emissions from the production process.

- Exponential increase in recycled content.

- Developing a robust circular economy that minimizes waste.

To this end, Mercedes-Benz is working with specialist partners and strengthening its own recycling infrastructure. A prime example is the pilot battery recycling facility in Kuppenheim, southern Germany, which is currently in the research and development phase and is essential for handling future high-voltage batteries.

Materials Innovation: 40 Sustainable Novelties

Over the past two years, the team behind Tomorrow XX has managed to identify and qualify no less than 40 new materials and components that are more sustainable and are to be integrated into future series models.

These innovations cover the entire vehicle, from the structure and bodywork, to the interior and braking systems.

The Pillars of the Tomorrow XX Project: The Circular Economy at Work

The project focuses on rethinking the way components are designed and produced, ensuring that, at the end of the machine's life cycle, valuable materials are recovered and reintroduced into the system in maximum quantity.

1. “Green” Steel: Production with Near Zero Emissions

Steel, an essential material, is transitioning to a near-zero-emission standard. Mercedes-Benz is abandoning the traditional blast furnace process in favor of an innovative technology: direct hydrogen-based metal reduction combined with the use of electric arc furnaces.

This change, along with increased recycled content, almost completely eliminates greenhouse gas emissions associated with steel production.

2. Waste Recycling: From Used Tires to Quality Plastic

Through chemical recycling, used tires are given a second life. They are transformed into pyrolysis oil, which, combined with certified biomethane from agricultural waste, is processed into plastic.

This recycled plastic offers the same level of quality as plastic made from fossil raw materials. The first applications are already visible: the door handles of new models are designed using exactly this revolutionary material.

3. From Recycled Airbags, into Vital Components

Even safety components end up being reused. Used airbags, made of glass-fiber reinforced polyamide, are recycled to create new parts, such as engine mounts and valve housings in the thermal management system.

4. Minimized Footprint Brake Pads

The braking system is not spared from this revolution. The new sustainable brake pads contain around 40% material from used pads, reducing CO2 emissions by up to 85% during the production phase. They are also combined with a backing plate made from the new "green" steel.

This is supported by the brand's in-house friction component processing system, called MeRSy.

The Final Vision: Almost 100% Recycling and Green Energy

Tomorrow XX is dedicated to implementing a circular economy that helps achieve a recycling rate of almost 100% within the production process.

At the same time, Mercedes-Benz is committed to using even more renewable energy in all its production sites worldwide, strengthening its “Ambition 2039” commitment (CO2 neutrality across the entire value chain). The Tomorrow XX project therefore represents a bold and necessary step, turning the vision of sustainability into reality for future generations of luxury vehicles.